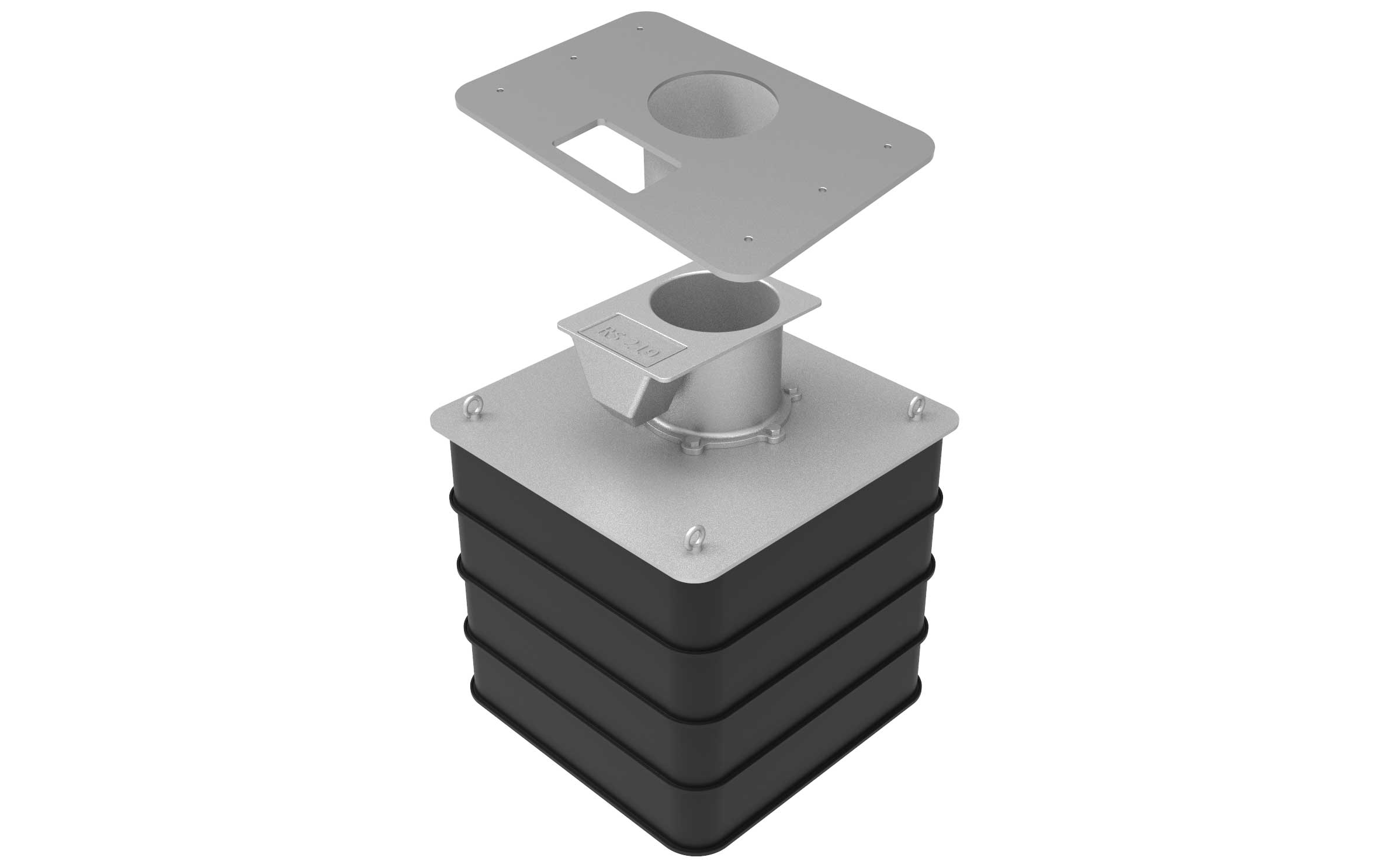

Retention Sockets

Hoop Bollards | Shell, Fradley

The team at NAL was approached to provide a solution to combat costly maintenance of pump protecting hoop bollards, situated on the forecourt, at a Shell filling station.

Subjected to inevitable vehicular impacts, bollards required regular repair and replacement and, having been installed via the traditional concrete method, excavation works were proving expensive and disruptive.

Recognising the benefits afforded, Shell, opted to install hoop bollards within NAL Retention Sockets. This shallow depth ground socket system has been designed to secure all types of non-illuminated street furniture, enabling easy removal in the event of impact with a key and spanner.

A depth of just 300 mm was excavated upon the removal of the old hoop bollard to house the sockets; therefore no underground forecourt equipment was compromised. On completion, the hoop bollard was placed into the socket and secured into position by tightening the retaining bolts, found within the side chamber. To eradicate any Health and Safety implications, if a socket is vacant whilst awaiting a replacement, it is securely closed off with a pedestrian plug to prevent trip hazards.

The installation was seamless, and civils work was completed prior to the installation of the bollards, which meant no conflict in schedules. In terms of future maintenance, and with no further excavation necessary in the event of damage, disruption and associated costs are significantly reduced.